PRINCE KNIT

DISCOVER THE COMPLETE LIFE CYCLE ANALYSIS CARRIED OUT BY INESCOP: THE PRESTIGIOUS SPANISH TECHNOLOGY INSTITUTE.

From the raw materials’ origins to the sneaker’s end of life, we partnered with INESCOP , to conduct the extensive analysis following the stringent guidelines set by the European Union.

IT’S WHAT WE DO AND HOW WE DO IT

-

RAW MATERIALS

+ info

2.17 kgRecycled plastic bottles from the bottom of the ocean

-

PACKAGING

0.24 kg

+ infoFrom the recycled cardboard shoebox to the ink printed on the tags

-

ADHESIVES

+ info

0.22 kgAny substance used to combine two parts

-

RAW MATERIALS ORIGINS

+ info

0.02 kgTransporting the raw materials from their origins to the factory

-

PRODUCTION WASTE

+ info

0.05 kgFrom shipping pallets to the paper factory workers use

-

CUTTING THE MATERIALS

+ info

0.16 kgLeftover material and its disposal (innovative knit process to avoid excess waste)

-

OVERALL ENERGY CONSUMPTION

+ info

0.83 kgType and amount of energy used

-

DISTRIBUTION & SALES

+ info

0.36 kgDistance from the factory to the distribution center and to the different points of sales

-

END OF LIFE

+ info

0.8 kgAssumed that 60% of sneakers end up in landfills, 33% incinerated, and 7% recycled

TOTAL 4,85 KG CO2

The average sneaker generates 13,6 kg CO2 (MIT)

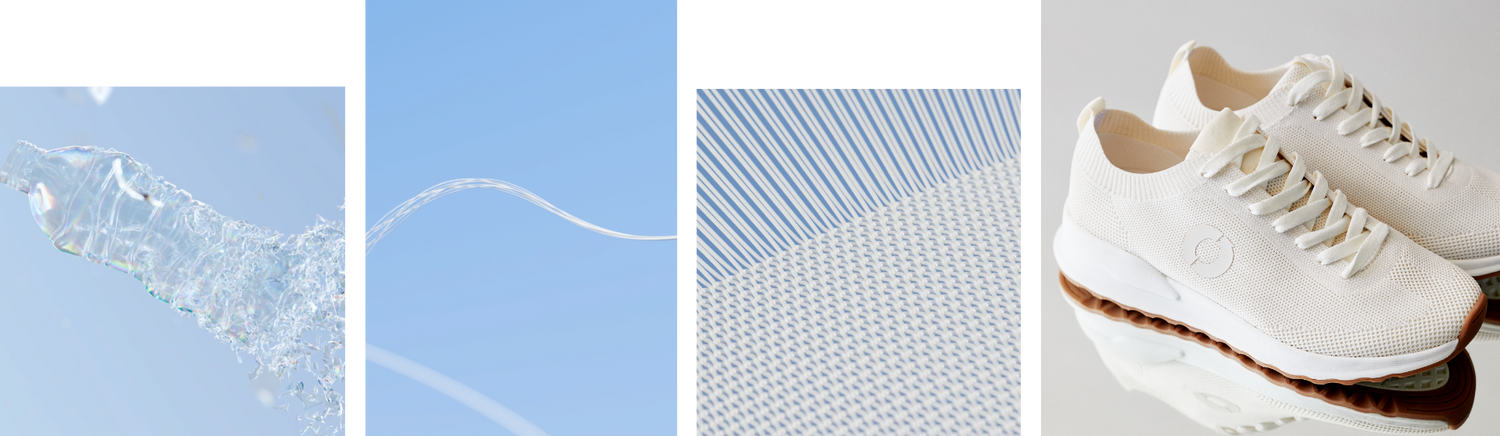

KNIT WITH OUR OCEAN YARN

The Prince Knit sneakers main fabric is made with our Ocean Yarn spun from plastic bottles collected from the bottom of the ocean through Ecoalf Foundation’s Upcycling the Oceans project.

“Even with every component taken into account we were able to receive a 4.85 kg carbon footprint, and, if the customer decides to recycle their sneakers, the impact is lowered to roughly 3,85 kg! This analysis is an important achievement for us on our path to becoming a zero emissions brand.”

Miguel Pomares, Head of Footwear at Ecoalf