Materiales

"We are proud to use the least amount of natural resources possible (materials, energy, and transportation)."

The development of new materials with a lower environmental impact has been the company's focus since its inception. We have used innovation to collaborate with our suppliers in the search for new fibers, materials, and processes to continually improve our fabrics.

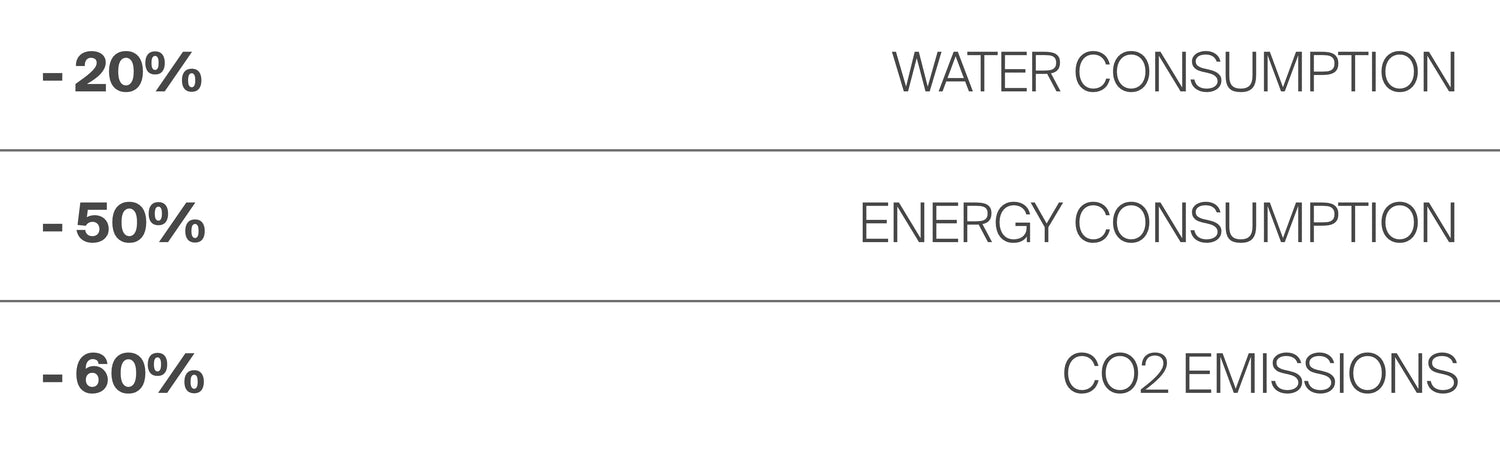

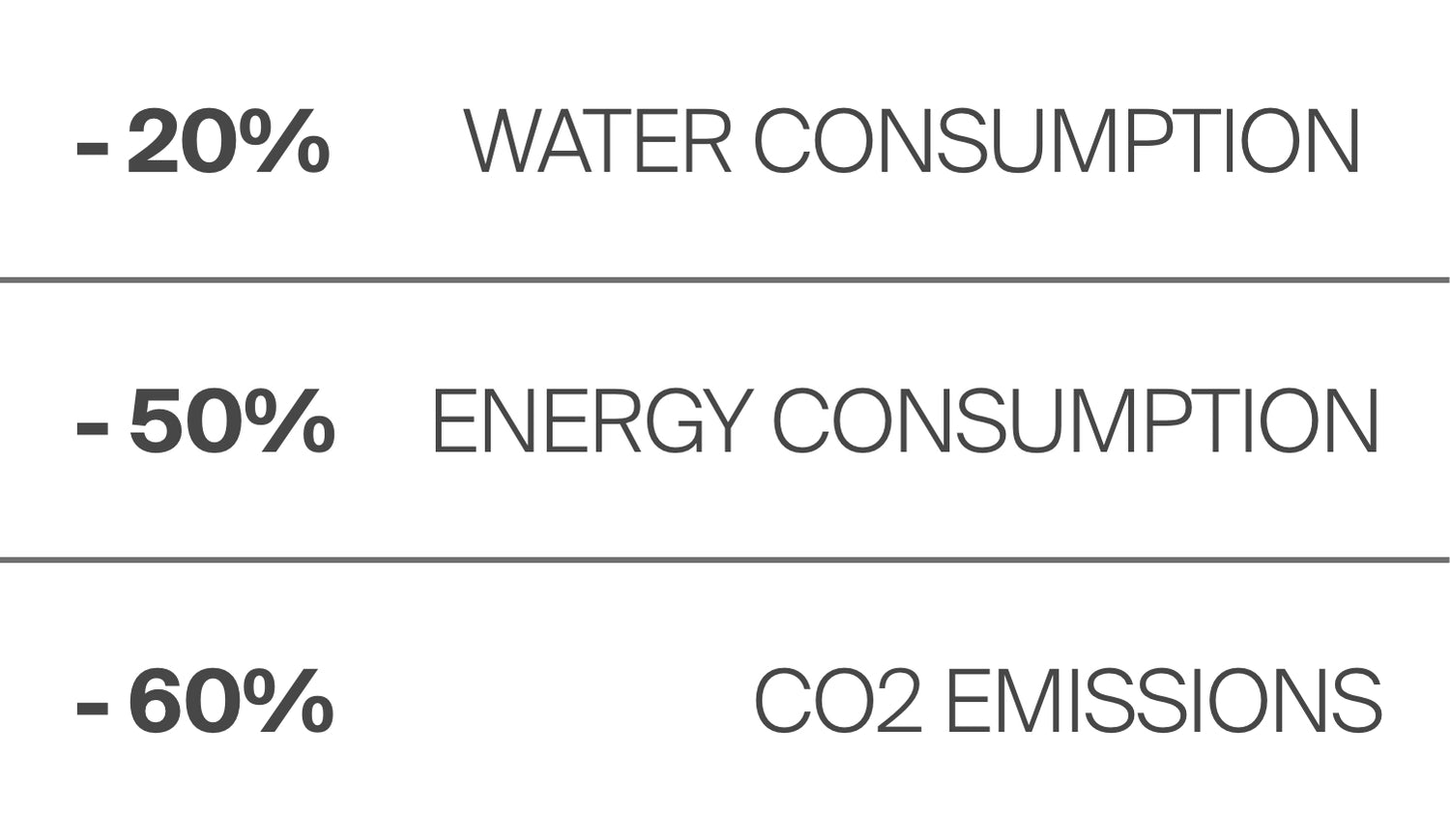

Since 2009, our mission has been to stop using the planet’s natural resources in a careless way. That's why we decided to use recycled materials, giving a second life to waste such as recycled nylon, polyester, wool, and cotton, reducing water consumption and CO2 emissions.

Now, we incorporate new materials of natural origin that, while not recycled, still have a low environmental impact, such as linen, hemp, cellulose fibers, or organic cotton.

ECOALF has been certified by the Global Recycled Standard (GRS) since 2017, reaffirming our commitment to the use of recycled materials. To maintain this certification, ECOALF undergoes annual audits that verify the traceability and chain of custody of GRS-certified products, as well as compliance with international labor rights and our environmental commitment.

Products labeled on our website under the GRS standard have been verified by certification bodies, ensuring the traceability of the recycled content up to ECOALF. Additionally, this certification guarantees that they have been manufactured in facilities audited under strict social, environmental, and chemical usage standards.

Additionally, since 2023, ECOALF has been certified under the Organic Content Standard (OCS), ensuring that the organic fiber content of OCS-certified products has been verified by a certification body.

To ensure a minimal impact in the dyeing and finishing processes of materials, our suppliers commit to not using toxic chemicals in our products by signing the LSR (List of Restricted Substances) and Vegan Guarantee.

We work with recycled polyester materials from different sources:

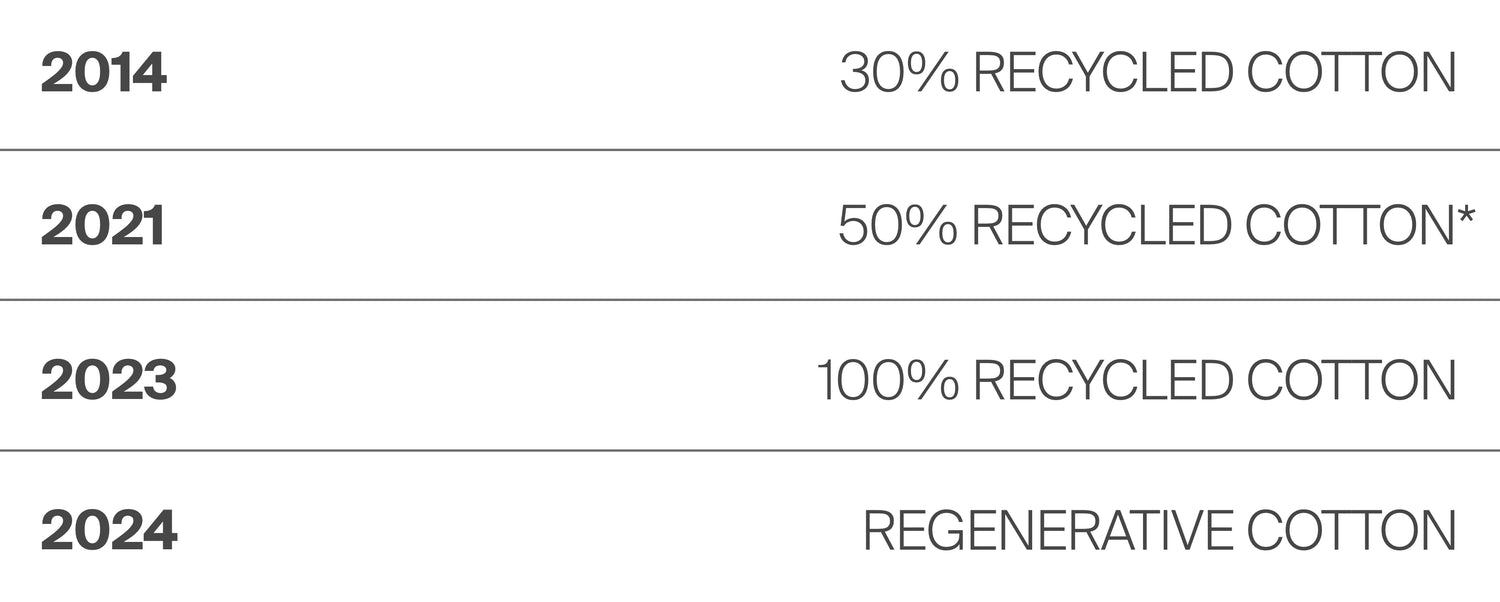

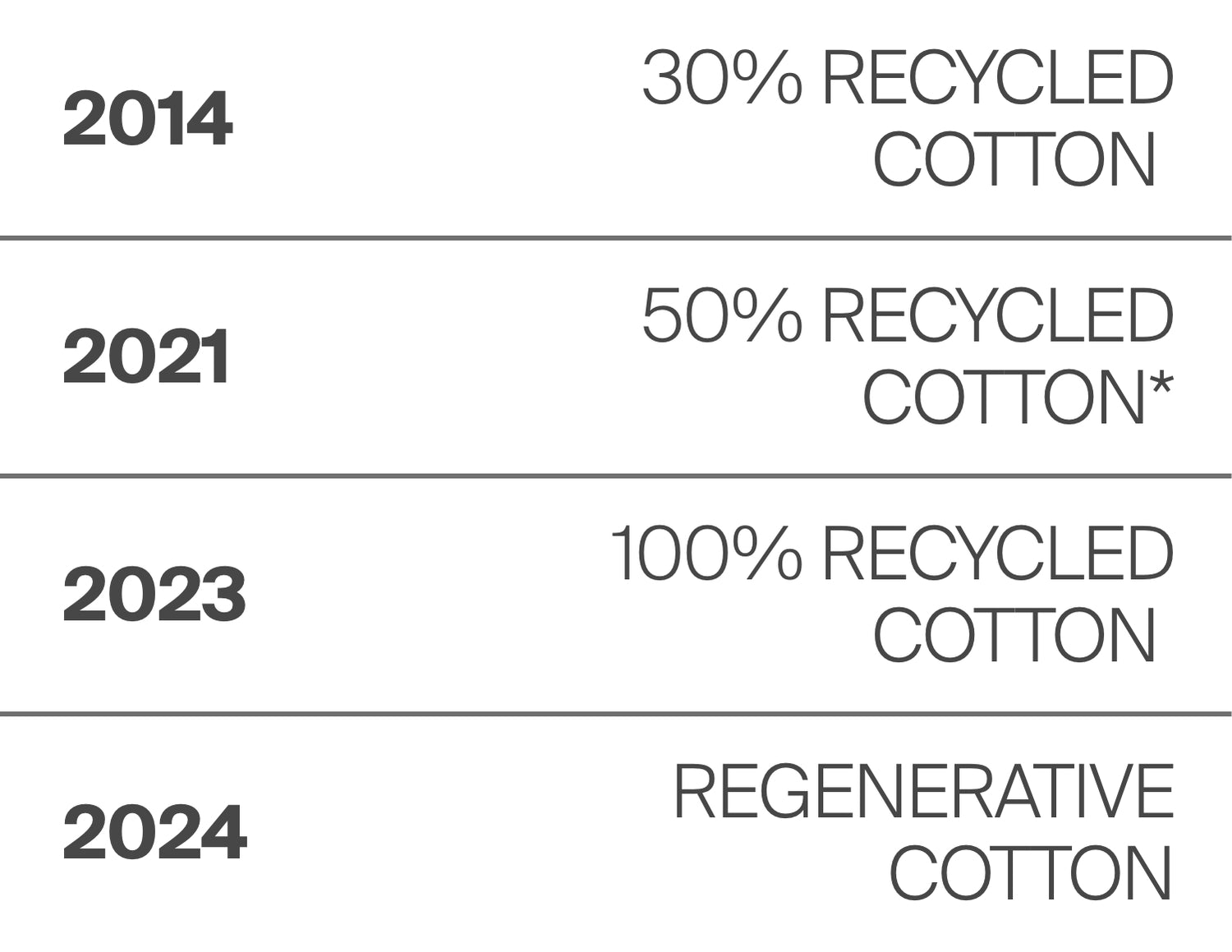

Due to its intensive water use during cultivation and production, one of the main environmental impacts of the textile industry comes from cotton.

Over half of cotton fields are artificially irrigated, and up to 90% of the water used is potable.

We have worked tirelessly for the past 12 years to develop high-quality recycled cotton as a substitute for conventional cotton.

MATERIALS

-

RECYCLED

WOOLWe have chosen recycled wool as an alternative to conventional wool. Recycled wool is a material that has been used since ancient times. Wool is recycled through a mechanical process similar to that used for cotton. To achieve this, we are working in two areas: selecting the raw material (post-industrial wool) and working on sustainable and innovative finishing processes that improve the final characteristics of the fiber, achieving a feel as similar as possible to virgin wool.

Watch video -

RECYCLED

CASHMEREFor our knitwear collection, we have chosen recycled cashmere as an alternative to virgin cashmere, as the latter has a high impact on the land where the goats are raised. Recycled cashmere limits this overproduction and overgrazing, as textile waste is recovered to become a raw material again.

-

Full width link in gallery

POST-CONSUMER

COFFEE GROUNDSThanks to our collaboration with the patent company to transform post-consumer coffee grounds into granules with technical properties, we can provide finishes to our garments that normally require chemical treatments. These properties include quick-drying, UV-ray protection, and odor control.

-

RECYCLED

TIRESOur flip-flop made from recycled-tire powder is the result of 2 years of R&D and innovation through a collaboration with Signus and the Technological Center for Shoes of La Rioja (CTCR). This is a 100% eco-designed product, developed and manufactured in Spain.

-

LINEN

Linen is a lightweight material, yet one of the strongest fabrics which allows it to last for many years. It is a low-impact natural fiber that consumes very little water during cultivation, and one hectare of linen can remove 3.7 tons of CO2 from the atmosphere.

-

KAPOK

Kapok is a type of seed from the Ceiba pentandra tree that can be converted into a soft fiber with a silky feel. Thanks to technological innovation, we have developed a fabric where kapok is blended with organic cotton, achieving a savings of over 4,000 liters of water per T-shirt compared to conventional cotton.

-

RECYCLED

NYLONRecycled nylon drastically reduces the number of steps in the production process compared to conventional processes. This reduction in processes leads to a decrease in CO2 emissions and water consumption. Recycled nylon can be recycled again when garments reach the end of their lifespan.

-

MICROPLASTIC-LIMITING

NYLONEvery year, approximately half a million tonnes of microplastics end up in the sea, simply from washing synthetic materials. The revolutionary Meryl® yarn is composed of 50% recycled nylon and uses hydrogen bonds to seal microfibers in and prevent microplastic pollution.

-

ARTIFICIAL

CELLULOSIC FIBERSTo manufacture these types of plant-based fabrics, wood pulp waste from sustainably managed forests is used, particularly from eucalyptus, although some comes from oak or birch trees. The plant material is crushed and transformed into pulp, and then into yarn or fiber. These types of fabrics are lightweight and have antibacterial, moisture-resistant, and durable properties.

"All our decisions must be made with the purpose of leaving a minimal environmental impact on the planet and people."

WE THINK CIRCULAR,

WE CREATE CIRCULAR

Achieving circularity is key to protecting natural resources and staying aligned with our purpose. For years, and with the goal of being circular, we have worked to make our designs mono-materials and easily recyclable. Additionally, we work to build circular supply chains, as in the case of MADE TO BE RE-MADE.

55% MONO-MATERIAL PRODUCTS IN 2022

REGENERATION ALLOWS US TO MOVE FROM A

LOW IMPACT TO A POSITIVE IMPACT.

Regeneration is our opportunity to reverse the textile sector's tendency of consuming and polluting water, depleting resources, exploiting the soil, inappropriate water use, waste generation, and overexploitation of the planet. It allows us to give back to the planet more than we extract from it, leaving a positive impact in our wake.

• Increases biodiversity and improves soil health.

• Improves efficient water use and reduces and captures greenhouse gas emissions.

• Improves the economic and social well-being of communities.

REGENERATIVE MERINO WOOL

In addition to our regenerative cotton capsules, we collaborate on a merino wool recovery project based on transhumance.

BENEFITS OF

TRANSUMANCE

-

IT INVOLVES EXTENSIVE LIVESTOCK FARMING THAT PROMOTES THE DISPERSAL OF SEEDS AND SOIL FERTILIZATION.

-

-

MAINTENANCE OF THE ETHNOGRAPHIC AND CULTURAL HERITAGE OF THE AREA.

-

-

CONSERVATION OF LIVESTOCK ROUTES AND NATIVE BREEDS

-