Planeta

”We currently find ourselves confronted with the biggest challenge humanity has ever faced, climate change”

We are the first generation to experience the consequences of climate change and, at the same time, the only one that can act to restrain its effects as much as possible. What we make of the next decade will be crucial for the future of humanity. According to the Paris agreement, within the United Nations Framework on Climate Change, it is necessary to establish measures that allow us to limit the worldwide temperature increase to 1,5 ºC. Additionally, we know that the fashion industry is the second most polluting industry on the planet.

All our actions inside Ecoalf are under constant evaluation with the goal of causing the least harm possible to the planet and local communities. We believe fashion cannot just be about looking good but also about doing what is right and feeling good about it. Fashion’s supply chain is very profound and complex, which is why we work on each and every process to minimize the impact as much as possible.

Every choice we make is part of our commitment to create a responsible business without compromising the future generations. During all these years we have worked hand in hand with all of our suppliers, using the most innovative technologies to develop more than 400 recycled fabrics with the same characteristics and quality as the best non recycled - but with a much lower environmental impact. Putting innovative processes into place has been fundamental for us to be able to develop high-quality materials.

We love to work with recycled materials because when we use waste as a raw material we are reducing the consumption of natural resources and offering a second life to trash, additionally, the production of these recycled fibers requires less energy & water. Even though 100% of our fabrics are sustainable, not all of them are recycled. We are constantly pushing the boundaries further and developing new materials of natural origin that are equally sustainable. We have created our own internal list of favorite materials, based on the fabrics more aligned with our purpose

"We are proud of using the least amount of natural resources as possible (materials, energy & transport)"

Recycled Materials

Since 2010 our goal is to reduce the consumption of natural resources, that’s why we decided to use recycled materials, such as synthetic nylon & polyester, that come from recycled sources and can be recycled many times. Global Recycling Standard (GRS) guarantees that all the fabrics we use come from recycled sources. Ecoalf is a GRS certified brand.

Organic cotton

Organic cotton has a smaller environmental impact compared to conventional cotton, as it does not allow the use of toxic pesticides or fertilisers, thus benefiting biodiversity.

Even though organic cotton requires less water, as it receives the majority from natural rainfall, it is a water-intensive crop to cultivate and produce.

That’s why we prefer to use recycled cotton, but, since the recycling process is quite complex our collections also include organic cotton qualities.

Organic cotton certified under the Global Organic Textile Standard (GOTS) guarantee:

+ INFO

The used seeds have not been genetically modified (GMO). Neither pesticides nor other chemical substances that harm the planet, humans and animals were used in its cultivation. The chemicals themselves used throughout the whole supply chain, whether it be additives, bleach, dyes, fixatives, prints… as well as the toxicity level of these chemicals when used with water, must all meet the standards of GOTS.

A post-consumer coffee grounds finish

Thanks to the collaboration we have with the company holding the patent for transforming coffee grounds into pellets with technical properties, we are able to give our garments finishes that would otherwise require chemical treatments.

These properties are: Fast drying. UV-protection & odor control.

+ INFO

The coffee grounds are collected every day from cafeterias and go through a process in which the first step is to remove the moisture using pressure and drying. That’s where the coffee grounds are separated from the oil that will be used for cosmetics. The coffee powder is then pressed, compacted and converted into pellets that are mixed with the PET or nylon pellets (both always recycled). Coffee grounds themselves cannot be converted into yarn, which is why they need to be combined with fabrics. This way, we obtain yarn that naturally contains all the properties coffee can give, without using chemicals.

Animal Source Materials: The filling of our down jackets

Our commitment also includes respecting animals. For years we’ve been working on alternatives for our jacket and coat filling to reduce the amount of feathers in our garments. During these last few years, we have tried all kinds of non-animal based alternatives. We principally worked with synthetic fillings that provided us with the same characteristics as feathers. But, by doing so, we ran into a problem. We had to use fillings made from virgin polyester, which contradicts our mission at Ecoalf.

Today we can proudly say that all of the synthetic filling we use to substitute feathers comes from recycled PET. Therefore, we are currently using the following fillings:

PrimaLoft®

A filling made with a mixture of 50% RSD feathers (Responsible Down Standard) and 50% polyester from recycled PET. The down we use is a mixture of water repellent fillings that are free of PCF and certified as RDS, Responsible Down Standards. RDS ensures that the down comes from ducks and geese that have had a dignified life, that have not suffered any form of abuse and whose feathers were plucked after the animal was killed. RDS encompasses the entire supply chain all the way from the farm up until the finished product. This way, the consumer has complete peace of mind that the entire chain has been accurately traced and verified.

Synthetic fibers

Synthetic fibers with a large heat capacity are used to make these fillings. They have great insulation properties which are maintained throughout the entire life-cycle of the product. They are easy to wash and to take care of, which guarantees longevity, and they can even be put into the dryer. The filling is 100% made from PET. A single garment could contain approximately 10 plastic bottles.

99.63% of our SS22 collection is vegan..

In 2019, we became a PETA Vegan certified brand and won the PETA Vegan Fashion Award. You will not find real fur, leather, or silk in our collections. This logo will help you to recognize the vegan Ecoalf products.

Our Suppliers

We can not tackle changing the fashion industry alone, we need to work closely with our suppliers and collaborators. We seek partners that share our values, that meet our sustainability standards, or, even better, that go beyond them. We have a very close relationship with them that allows us to influence their processes, working to lower the impact our products have.

”TRANSPARENCY ALL ALONG OUR SUPPLY CHAIN & MANUFACTURING IS KEY FOR THE ORGANIZATION.”

Our sustainable environmental management includes the transparency in our supply chain being able to trace Tier 1, Tier 2 and Tier 3 to guarantee that all processes meet the correct environmental management in all of their facilities.

To ensure this and minimize the environmental risks, all our suppliers are certified and audited by third parties. These are the certifications we require:

Restricted Substances List (RSL)

10 years ago we were very focused on the raw materials our sustainable fabrics were made of, however, we realized that how the fabrics are made is just as important as the origin of its fibers.

So, we decided to develop our Restricted Substances List, because an Ecoalf garment requires that we use safe chemicals throughout our supply chain.

We require all our suppliers to sign our RSL to guarantee their use of the safer chemicals as well as the correct chemical management.

“If you can’t measure it, you can’t improve it” Peter Drucker

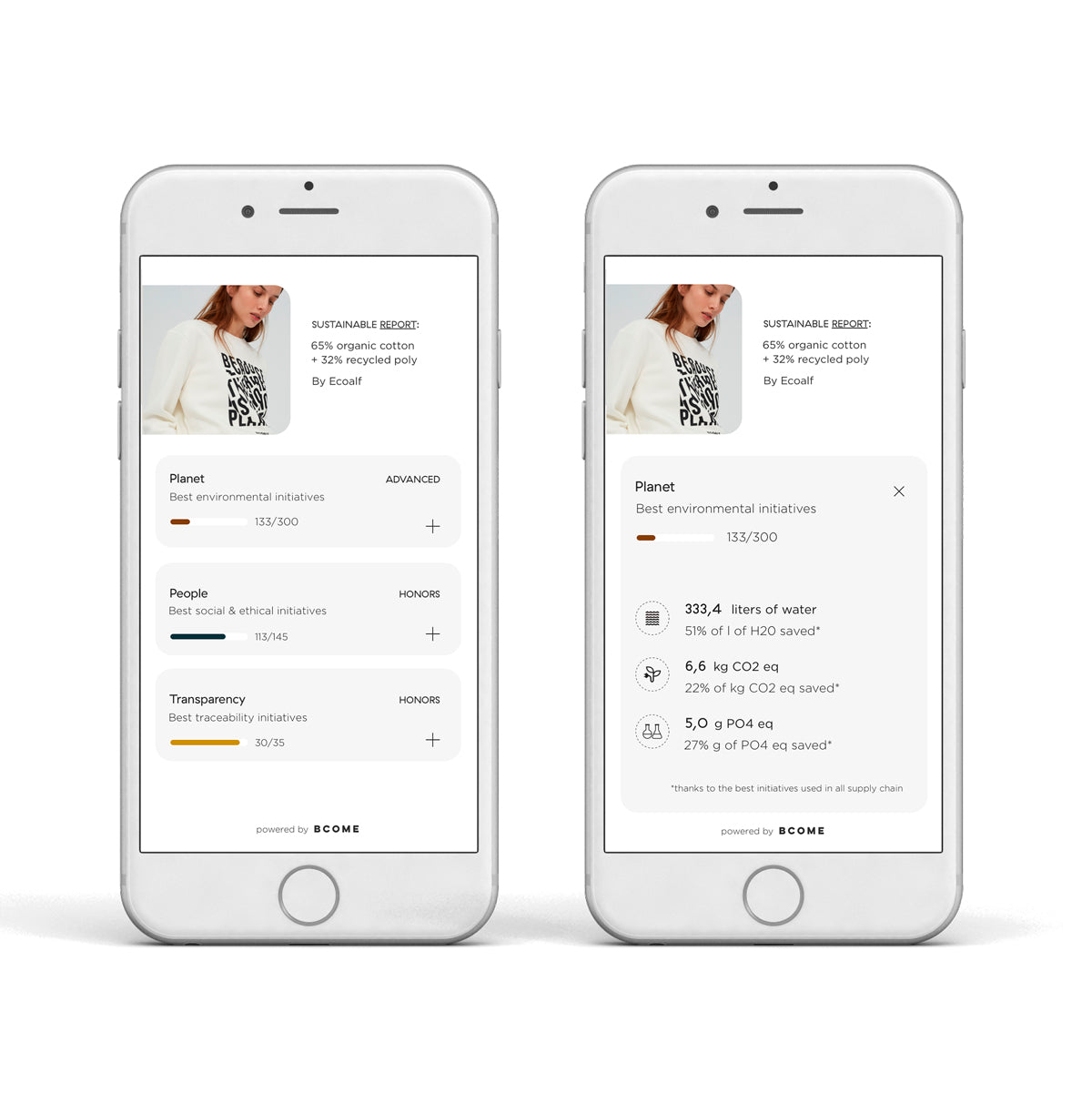

We believe the only way to reduce our impact is to trace our supply chain and to measure the environmental impact that each of our products has.

The evaluation technology is helping us to translate this information into quantitative impacts that we can share with our stakeholders.

Transparency connects customers with the unique story that is behind each garment.

We can share the amount of water used and CO2 emitted, as well as the amounts saved, the materials’ sources and number of processes involved throughout the value chain. This allows customers to understand the products’ history and make an informed decision that aligns with their values.

We can share the amount of water used and CO2 emitted, as well as the amounts saved, the materials’ sources and number of processes involved throughout the value chain. This allows customers to understand the products’ history and make an informed decision that aligns with their values.

An important step towards complete transparency is incorporating the detailed impact of some of our SS20 garments thanks to the evaluation technology developed by BCOME.

The assessment for each garment is based in these areas:

• Planet

• People

• Transparency

”Every time a garment is washed, small particles of fibers (mirofibers) are released into the water system and those microfibers eventually end up into the oceans.”

As part of our mission to protect the oceans and to fight marine plastic pollution, we are committed to developing solutions to the microfibres issue. Every time a garment is washed, small particles of fibers (microfibers) are released into the water system and those microfibers eventually end up into the oceans. Microfibers will remain in the oceans undermining the ecosystems and entering in the food chain.

In collaboration with LEITAT (Microplastic textile discharge testing conducted under the protocol developed by Leitat), we were able to meticulously evaluate the amount of microfibers our different fabrics discharge.We understand the complexity of the microfiber issue, we know it is going to be a long journey, but step by step we are introducing changes in our products to reduce their microfiber pollution.

What we’ve changed

According to the results obtained during the MERMAID Study, we realize that yarns with continuous fibers release less microfibers than yarns composed of discontinuous or staple fibers. Most of our jackets are made with continuous filaments.

Fabrics with short fibers release larger quantities of microfibers, such as synthetic micropolar fleece, synthetic corduroy, fake fur, synthetic velvet and flock print. That is why, in 2015, we stopped producing fleece, even though it was one of our best sellers, and in general, all of the other fabrics mentioned.

What you can help to change:

WASH ON LOW TEMPERATURES: Temperature is a factor to be taken into account regarding the quantity of microfibers being released. Washing clothes at low temperatures can decrease the number of microfibers released during a rinse cycle.

USE LIQUID DETERGENTS: The kind of detergent used can also limit the release of microfibers. Liquid detergent is the best option as powdered detergent provokes larger amounts of microfiber runoff.

WASH LESS FREQUENTLY: By reducing how frequently you wash your clothes, you also reduce the volume of microfibers your clothing expels.