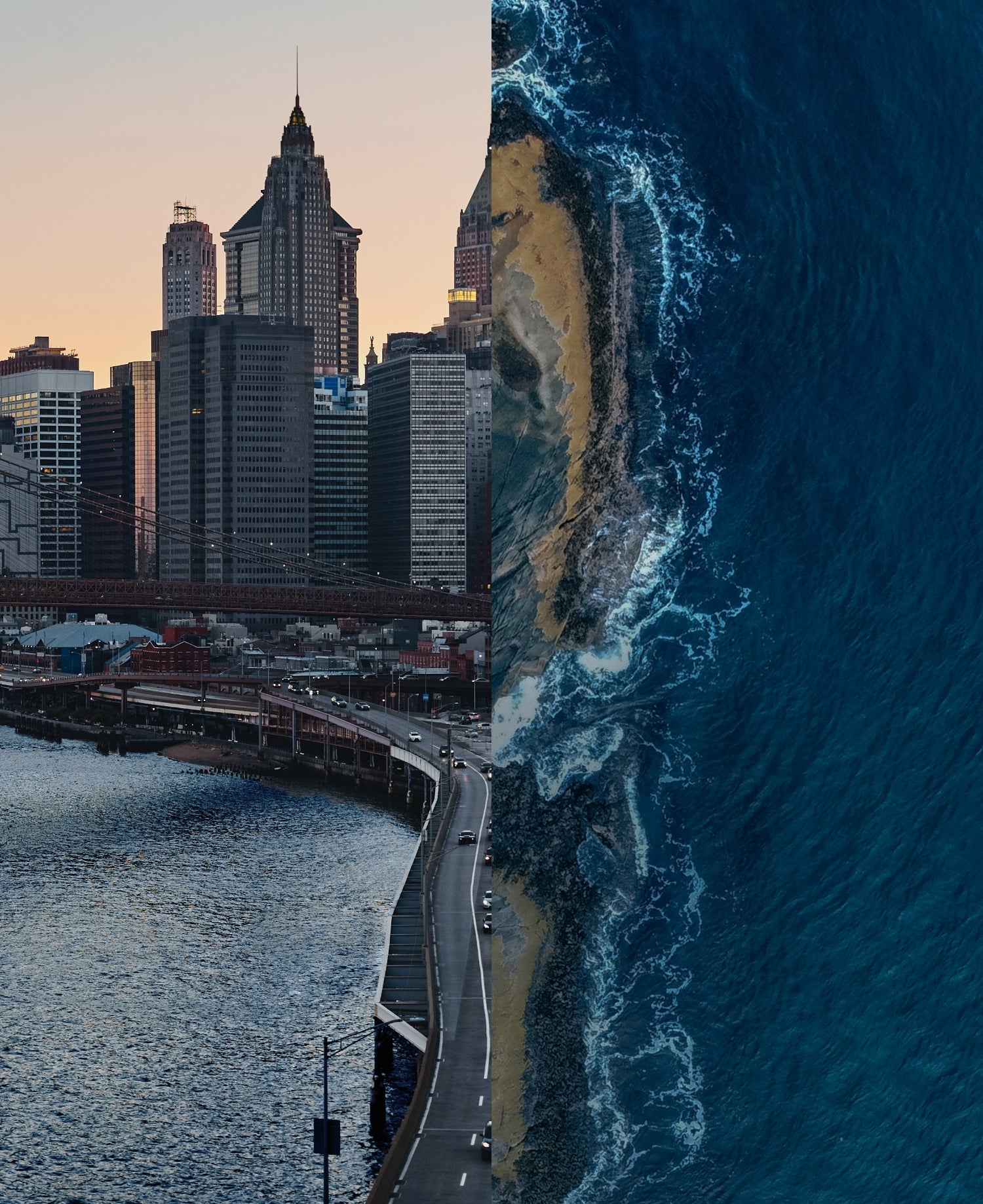

WATER SCARCITY

The fashion industry uses about 79 trillion liters of water each year.1 New York City consumes approximately 3.8 billion liters of water a day.2 That means that what the fashion industry uses each year is the equivalent of supplying all the drinking, cleaning and maintenance water for New York City for the next 57 years.

An astounding 2 billion T-shirts are sold annually,3 each demanding a staggering 1,104 liters of water for production,4 enough to sustain an individual for nearly a year. The fashion industry's current water usage could meet the needs of 110 million people annually.5 We need to make a change to the current business model.

WATER IS OUR LIFELINE

We must revolutionize the fashion industry to safeguard it. Ecoalf is offering solutions, committed to preserving our water sources on three vital fronts: employing low-impact recycled materials, adopting responsible dyeing processes, and innovating materials to combat microplastic pollution.

RECYCLED COTTON: A RESURGENCE OF HOPE FOR DRIED-UP WATERS

Take a look at the Aral Sea, once the fourth-largest lake globally, today has become a desert as 90% of the water has disappeared as a result of unsustainable cotton cultivation. About 3% of the world’s surface is used for cotton production. More than half of cotton fields are irrigated artificially and up to 90% of the water used is drinkable.

450 MILLION LITERS OF WATER SAVED THIS SEASON

This Spring-Summer 2024 season, we have saved over 450 million liters of water by using recycled cotton (reducing its water footprint by 98% compared to conventional cotton garments)6

GARMENT DYEING: TRANSFORMING FASHION WITH A SPLASH OF RESPONSIBILITY

Dyeing in the textile industry not only consumes considerable amounts of water (85% of the water used in the industry) but also contaminates it upon using it. Ecoalf has incorporated garment dyeing and uses machines that minimize water usage while returning the used water to the ecosystem clean and unpolluted. This approach reduces the environmental impact and imparts a unique, washed look to each garment.

PREVENTING MICROPLASTIC POLLUTION

Over one-third of ocean microplastics originate from synthetic clothing7., and nearly half of our garments are made of plastic, shedding up to 700,000 fibers per wash8. Ecoalf combats this silent threat by prioritizing long, continuous fibers across its collections and championing recycled nylon – the synthetic material that releases the least amount of microplastics.

1. UN Web TV

2. United States Environmental Protection Agency

3. TEDEd

4. Powered by BCOME

5. The Carbon Circle